Many start-up founders tend to partner themselves with large manufacturing facilities, however, majority of them get burned badly. But there are also founders whom benefit from this relationship. For this approach, seeing from the perspective of a contract manufacturer will help you have a better understanding.

Contract Manufactures (CMs)

The core management methodology of an established company is based on KPI (key performance indicator). In the manufacturing industry, the general idea is that low margin per each item, generates profit through large-scale production and shipment. A contract manufacturer is always looking for revenue and profit. So, whoever can hire the factory for large-scale manufacturing, will be given the highest priority.

A startup founder must produce an order the contract manufacturer is satisfied with, or convince the factory manager that there will be a high shipment volume. If not, the startup will be listed as low priority, and the support from the factory will be below expectations. It’s common knowledge that startups begin stagnating at this stage, because they cannot afford high production runs, leaving startups scratching their heads for the next steps.

Startup Tips When Manufacturing

When working with a tier one manufacturer, except for the selected lucky ones, it’s quite often that the CM assigns their (B), or (C) team to work on a startup’s project, while the (A) teams are assigned to serve the more important clients. What this means is, even working with World-class manufactures like Foxconn can still be as troublesome as working with local manufactures. Keep in mind CMs can only survive by taking on large production runs, not small production runs.

For start-ups, finding the RIGHT manufacturing partner is far better than finding a BIG factory partner, here are some elements to consider:

Firstly: Take into consideration the size of your forecast purchase order vs the capacity of the factory. Ideally the percentage is 5-10%, if the percentage is too low, you will lose priority.

Secondly: Management counts, a lot!: during your audit of a manufacturing partner, pay close attention to their management style, in many cases, the size of a company is not equivalent to the management level/style.

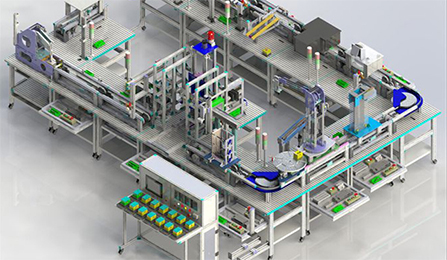

Thirdly: The engineering capability. Since a startup’s project has more or less many design defects, the engineering capability of a factory will help a lot in the transition of production, making sure the factory owns the engineering capabilities that matches the technical challenges of your project.

It’s not always easy to find the right partner, however, it is a task that needs to be done. If you are looking for a Chinese manufacturer just keep in mind these tips. Always understand that you won’t be the highest priority in a CM’s eyes. Whoever you decide to go with, ensure they have the right set-up to maintain high quality, with easy open communication channels, and most of all make sure they are trustworthy!