How is a PCBA made? What does the process look like? In many circumstances, people underestimate the amount of time and dedication which goes into producing these unique boards. Here’s a summary of the process.

The SMT line:

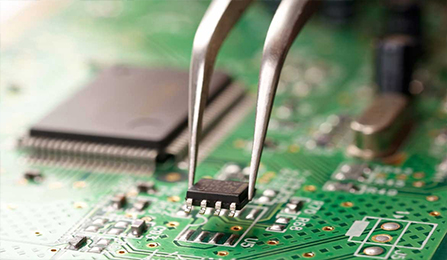

SMT (surface-mount technology) is the process which produces the PCB-A (plastic circuit board – assembled) a.k.a the motherboard. Firstly the PCB is cut out of its frame. The board is then fed into the solder paste machine whereby a stencil is used to place the solder in the correct place. The board then moves onto be checked before entering the pick-and-place machine. The pick-and-place machine places the components onto the board. Next, the board goes through the reflow oven. Inside the oven, the solder is heated and melts to connect the board with the components.

Testing:

Once the board exits the reflow oven it is then exposed to numerous tests. One being an AOI (Automated Optical Inspection). This test is to visually determine if the components are in the correct place. Next, the board goes through the ICT (In-Circuit Test), a jig/fixture is used to test the electrical current within the board, ensuring everything is connected.

Your PCBA is complete!