Product development is longer than you might think and the process is arduous unless you know what to expect. Here is a summary of what to expect and the process a product must go through. Note: certification is a separate process

Prototype:

You got your seed fund, you have now raised further capital, your design files are all in order, and now you have a working prototype. Great! This is a crucial milestone in your product development. Now it’s time to validate your product, refine the design, and optimize it ready for manufacturing.

EVT/DVT/PVT/MP1:

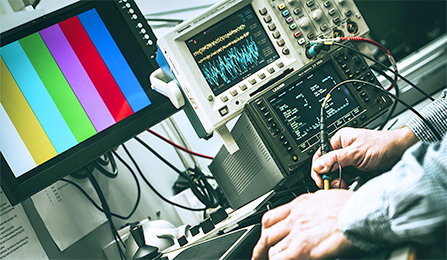

EVT (electrical) is the first validation stage of your product. Can also be considered as the bottleneck of your development. EVT is designed to validate key components, testing the design files, and testing your first five samples. These tests are a combination of field testing (real-life environment) and in-lab testing (simulation testing).

DVT (design) once EVT is complete your product them moves onto the design validation stage. You begin creating your molding and tooling at this stage. Also applying the same type of tests to ensure your product’s design is optimal. There should be no issues at this stage with the design.

PVT (product) at this stage your product is close to manufacturing. You would tend to run your first small batch (100+ units) on the manufacturing lines. This is to simulate what to expect during manufacturing. It also allows the factory to create an SOP (standard operating procedure) for an easy transition to mass production later on.

MP1 (mass production 1st batch) last but most importantly your product will now be manufactured. However, still running a small batch of 1000+ units. This stage is to ensure there are absolutely no issues with the product, tooling, and molding before increasing the production rate into the 10,000+ units.

Congratz! Now your product is manufacturing full whack. That is a summary of your product development. Estimated time (if in China) 9 months+