All IoT journeys inevitably start with a prototype. No matter how confident and optimistic you are with your digital idea, plunging directly into a full-fledged connected solution would mostly do more harm than good. At the end of the day, you might find yourself squandering all the resources on a product that isn’t technically and/or commercially viable.

Tech projects used to take years to move from conception to market. But given the whirlwind speed of today’s IoT world, companies can no longer afford such a long development cycle. The Agile Manifesto, originally intended for software development, has quickly extended its relevance to hardware development, paving the way to an era of rapid prototyping.

Custom vs Off-the-Shelf

There’s an inherent reason why building your custom rapid prototype outweighs going for a commercial product in an IoT project. In many cases, there’s just no out-of-the-box connected device out there that can fully meet your application requirements, particularly when it comes to industrial deployment. Take temperature sensors as a simple example. Depending on the industrial use case in question, there could be a bewildering variety in sensor requirements – from temperature range and accuracy to response time and stability.

You might ponder over making adaptations on an off-the-shelf IoT sensor to make it workable in the specific use case. The truth is, this won’t give you full flexibility and control over all elements in product design and costs. While it might serve as a temporary solution during a Proof-of-Concept where there’s a small number of test devices, this approach isn’t scalable enough for the future roll-out. The business case won’t work if you have to modify every one of hundreds or even thousands of devices.

A Hybrid, Plug-and-Play Approach to IoT Rapid Prototyping

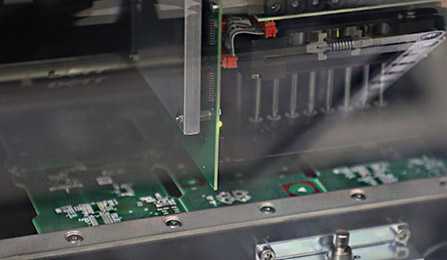

Building your own IoT prototype doesn’t necessarily mean you have to start from scratch. While a commercial connected device won’t serve you, there are numerous off-the-shelf development components that can make the process of rapid prototyping custom devices simple and painless. Plus, these components are highly affordable and easily sourced. With standards for embedded systems, developers can assemble and get their first prototype up and running in a matter of days and with minimal resources.

From a growing portfolio of hundreds of compatible development boards, microcontrollers, sensors, RF modules, displays and more, you can easily mix and match the click boards to quickly create a functional prototype that best caters to your use-case needs. Besides plug-and-play hardware development tools, there are also standards for writing application codes to make the code portable over different hardware platforms, further simplifying your development process.

Building a custom IoT prototype using commercial tools is the most viable and cost-effective way to test your product idea and select the right technology stack from the outset of your IoT project.

Outsource / Hire an Engineering Firm

On the other hand, if you’re one of the lucky startups who have secured funding. You can outsource the prototyping development to an engineering firm. IoT products more than likely use an existing framework that is already on the market. So, instead of ‘re-inventing’ the wheel by spending huge amounts of time on developing the ‘perfect’ device, outsource the development to an engineering firm, freeing up your time to focus more on the software and marketing aspects of your company.

In any circumstances, this has been proven to be beneficial. For one, a successful firm would have a strong understanding of the product you’re developing. Secondly, the prototype being developed will have manufacture-ready sourced components from the early stages of development, making it easier to transition to manufacturing when ready.