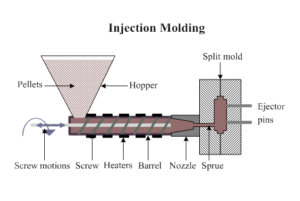

The most popular process in manufacturing is injection molding. This process is what creates the casing for your products, or the product itself (if it’s just plastic). Injection molding is a simple process which is commonly used in the manufacturing process.

The Process

Firstly, a mold is required. This is usually made of steel and has been wire cut to produce the necessary shape. Inside the mold will be a cavity, this cavity is what forms the desired shape of your product.

Once the mold is in place, resin (pellets) is inserted into the hopper which is then fed into the barrel. The plastic resin is then pushed along the barrel by a screw. By the time the resin reaches the nozzle, it (the resin pellets) would have become liquid. The screw then ‘injects’ the melted plastic through the sprue into the mold. Once the plastic has cooled (usually at an accelerated rate) the mold will open and the finished product will be ejected from the mold.

If you have any questions feel free to contact us.

Written By: F. Bravey