Deciding where to build your product is probably the most important first step of any project. Product development will be the most crucial aspect of your product’s life-cycle. While there are a number of options – such as, makerspaces, accelerators, and production partners – where you take that first step will decide how and when your project takes off.

Makerspaces, accelerators, and incubators

Makerspaces

Makerspaces allow you to try and fail. Because, they encourage brainstorming that enables you to practice new techniques and build prototypes before you manufacture. This is not the acceleration most startups are looking for which sees many startups become stasis in their product development. Without the impetus to build, you’ll get stuck in this stage puttering around on the same ideas without real growth.

Accelerators/ Incubators

Then you have accelerators/incubators. These types of facilities/programs can quickly push your startup through the development process and leave you with a functioning prototype. However, you will more than likely have lost (X%) of your equity without clear direction steps ahead. This is not a one-stop solution. As a startup you will be attracted to the benefits which these programs offer, but keep in-mind these types of programs are not designed for scale. They (not all) lack the community expertise/network to get your product to manufacturing.

Direct Development

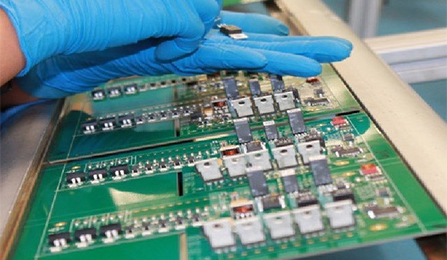

Or maybe you’ve already raised capital and are ready to build. This means your idea has been validated and you have a good hype. Then you have a third option. Partnering with a 3rd party engineering company, (service for fee) so you don’t end up losing your company (X% equity) before it begins. Engineering companies (hardware startup focused) are designed to have your prototype made market-ready, and manufacture-ready. These companies are experts in optimizing your product, and accelerating the timeline.

Or you have the option to skip all options and work directly with a factory. This could potentially cause devastating outcomes for numerous factors. They build for scale, they are not an innovation powerhouse, quality could be disrupted, IP issues, etc… However, there have been cases where startups have done this option and succeeded. It’s always best to keep in mind that choosing the right manufacturing partner requires a strong due diligence before you decide.

Conclusion

Whether you build with an accelerator, makerspace, or engineering company, whoever it’s with, make it a rule of phumb to think long term and compare it to short term solutions. As a startup the last thing you would want is to give away all your equity only to become an employee within your own company, compared to not having the expertise to get to a market-ready product.

Written by: Frederick Bravey