We encounter many problems throughout product development. We try and select the different ways to build our prototypes. One avenue we use is 3D printing. Printing a prototype can sometimes be the wrong move for your overall product, and I’m going to explain why.

What’s Wrong With 3D Printing?

A 3D printer has the capability to print any form or structure, using an additive technique. However, some start-ups spend months developing their product around a 3D printed design but end up spending even longer working with the factory, and tooling maker, to modify the design so that it is feasible for tool building, and injection molding. When your product is ready to scale in the factories, it needs to be produced according to the factory’s etiquette. You cannot get this from a 3D print.

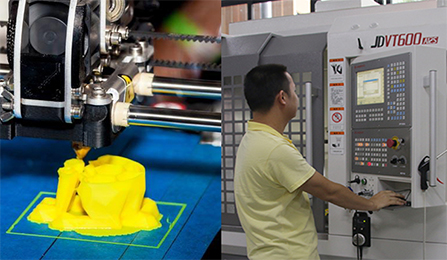

Other issues that arise when using a 3D printer is, that you will be left with a soft mold. A 3D printer commonly uses ABS, nylon, and PLA materials, including wax. However, a CNC machine uses much harder materials such as aluminum, hardwoods, steel, and titanium. So keep in mind what will better suit your product. A 3D print maybe feasible, and convenient for the early stages, however, will become obsolete further through the stages of your hardware’s development.

The future of 3D printing hasn’t caught up with the quality of the marketplace yet unless you want to spend thousands. If you are creating a prototype then perhaps a 3D printer will be more suited, however, the future still lies in using CNC machines and injection molding techniques.

For a works-like, looks-like prototype then 3D printing is the way forward to accomplish this, however, don’t be naive, and think that you can create a complete product on the back of a 3D print. Higher quality products are determined by the machines and money you use.

Written by: Frederick Bravey